Technical performance and usage instructions for precision panel saws

1、 Purpose and structural characteristics

Precision panel saws can cut and process various solid wood panels, Engineered wood, ABS panels, PVC panels, organic glass panels and other panels similar to wood structure and hardness. They are one of the necessary equipment in furniture manufacturing, decoration and other industries.

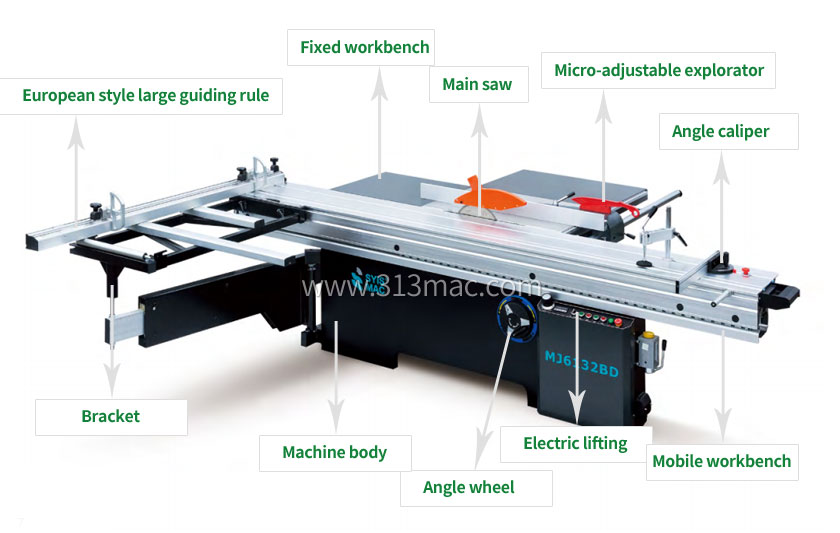

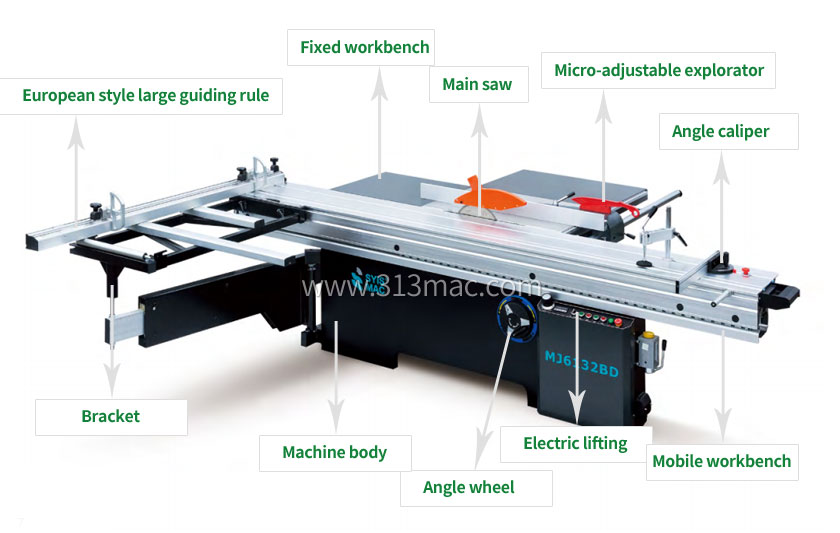

The precision panel saws is composed of a body, a mobile workbench, a mobile workbench with a bracket, a fixed workbench, a main saw, a scoring saw, a transmission lifting mechanism, horizontal and vertical guide plates, etc. The machine tool guide rail is made of aluminum alloy linear guide rail, which is oxidized and highly wear-resistant without deformation. This ensures that the precision panel saws can work accurately for a long time, and the inclination angle of the main saw blade and the scoring saw blade is visually displayed by a precision angle meter, making operation very convenient.

panel saws structure diagram

2、 Installation and debugging

1. The positioning of precision panel saws should be selected on hard ground or a specialized foundation. After the entire machine is positioned, the bed level should be adjusted to ensure the accuracy of the machine tool.

2. After the machine is positioned, adjust the connecting bolts between the fixed workbench, the mobile workbench and the bed to ensure the coincidence between the fixed workbench and the mobile workbench. Adjust the parallelism of the mobile workbench to the main saw blade, adjust the parallelism of the longitudinal guide plate to the main saw, and adjust the verticality of the transverse guide plate to the main saw, so that all indicators meet the precision requirements of the machine.

3. The above indicators have been adjusted before leaving the factory, and users only need to inspect each indicator. If there is an error, please ask professional technicians to adjust it. After adjustment, there is generally no need to make any further adjustments.

3、 Usage and Maintenance

1. Using

After the adjustment of the precision cutting saw meets the precision requirements, it can be powered on for testing. Before operation, rotate each handle, handle, and check if the triangular belt and other transmission mechanisms have any impact on their functions due to transportation. Before formal operation, it is necessary to jog and test run the saw blade to confirm the correct direction before it can be put into normal use.

Use a small board to test the saw without cutting it off. Rotate the handle on the right side of the machine tool to adjust the overlap between the scoring saw blade and the main saw blade.

Pull out and rotate the stop pin at the end of the workbench, and the workbench can be moved. Install suitable main saw blades and scoring saw blades at both ends.

When using a trapezoidal saw blade for marking, adjust the height of the marking saw blade so that the cutting width of the marking saw blade is slightly wider than the cutting width of the main saw blade. Adjust the height of the main saw blade so that the top of the serrated wheel is exposed for about 7 mm of operation. When the flatness error of the board is large, a combination type scoring saw blade should be used to adjust the gasket inside to slightly wider than the main saw blade. After adjustment, it must be confirmed that the adjusted part is tight before production can proceed.

2. Maintenance

Precision board saws should use vacuum equipment

Each shift should focus on connecting moving parts, workbenches, guide rail surfaces, and machine internal organs. When the workload is heavy, clean them in a timely manner according to the situation to ensure their accuracy.

Each shift's oiling area: fixed workbench, guide rail, and machined surface.

Each shift's refueling position: motor rotation shaft, scoring saw blade lifting rotation shaft, screw rod, screw nut, and relative rotation and sliding joints.

The guide rails of the mobile workbench should be particularly clean and lubricated with mechanical lubricant.

4、 Safety precautions

1. The precision cutting saw blade guard can protect the safety of the operator and cannot be easily removed during use.

2. When cleaning, replacing saw blades, or repairing, the power should be turned off and the machine tool should be completely stopped before proceeding.

3. Never approach the saw blade with your hands during operation, cutting small and narrow workpieces.