Introduction to common functions of edge banding machines

Usage of edge banding machine: Suitable for mass production of edge banding in panel furniture factories, it can seal wood veneer, PVC board, etc.

1、 Features of edge banding machine

(1) The edge banding machine adopts touch screen operation.

(2) The edge banding machine has a fault alarm device that automatically shuts down when a fault occurs. The well has the ability to automatically detect faults and is easy to identify the cause of the fault.

(3) When the edge banding machine is powered off, its set value can maintain a 5-year memory, and the program has permanent memory.

(4) Portable manual button switch jog function can be used during panel testing.

(5) The structure design of the edge banding machine is reasonable, the appearance design is beautiful, and the price is moderate.

2、 Introduction to the functions of the edge banding machine:

1) Hanging edge guiding rule: When placing the edge sealing board, ensure that the edge sealing surface of the board is parallel to the direction of conveyor belt movement, so as to ensure that there will be no edge sealing quality problems in the subsequent edge sealing process. The default setting is 35mm away from the conveyor chain edge.

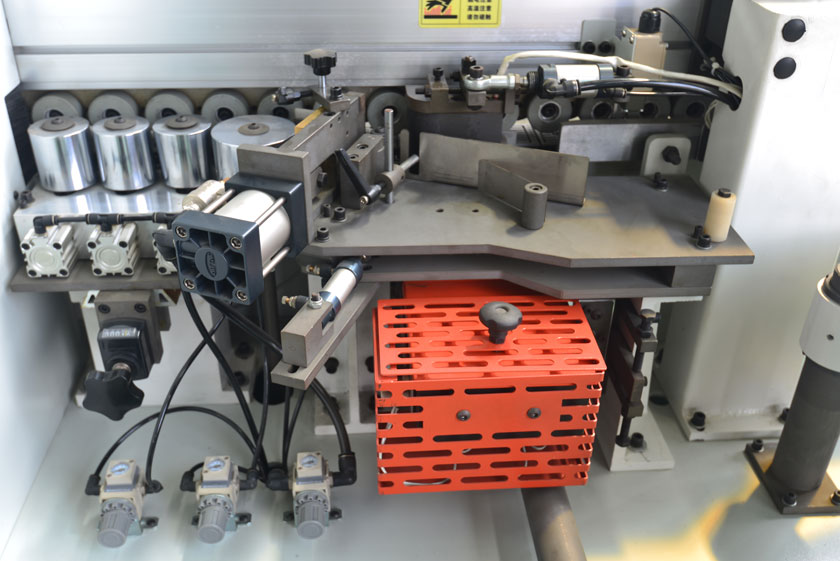

2) Disc component: rotatable, used for placing edge banding strips. The disc surface is on the same plane as the adhesive coated plate to facilitate the horizontal feeding of edge banding strips.

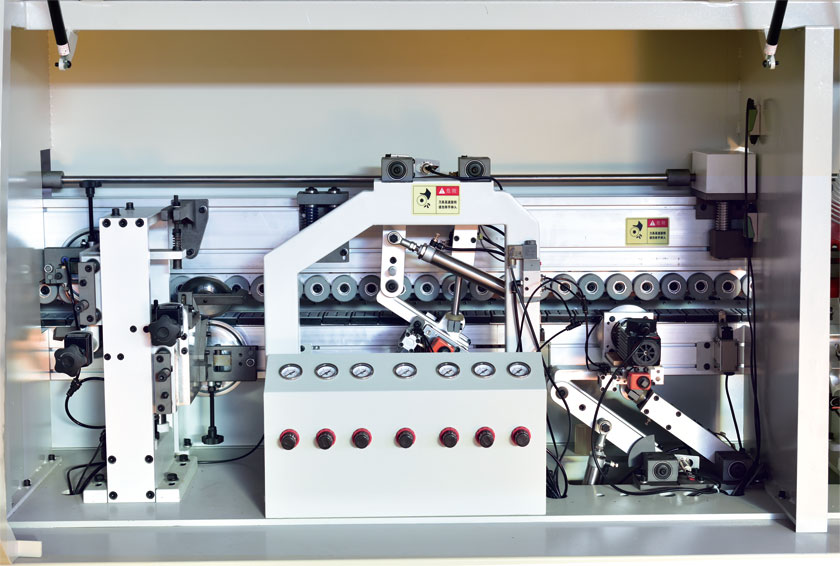

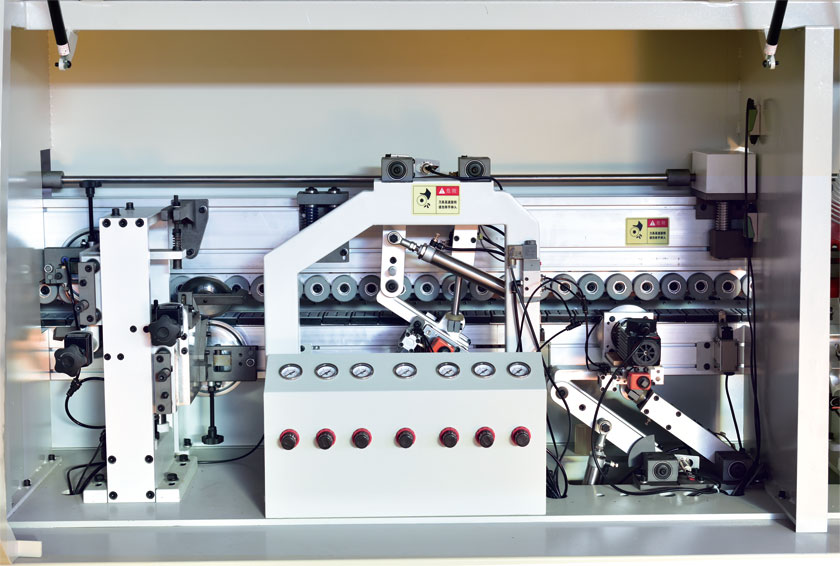

3) Beam pressing component: Together with the conveying component, the wooden board is pressed tightly to prevent deformation during processing, ensuring the quality of the board. The degree of tightness and adaptability to different plate thicknesses can be adjusted through the "beam lifting adjustment position".

4) Conveying component: Together with the pressure beam component, it controls the smooth transmission of the wooden board from the inlet to the outlet;

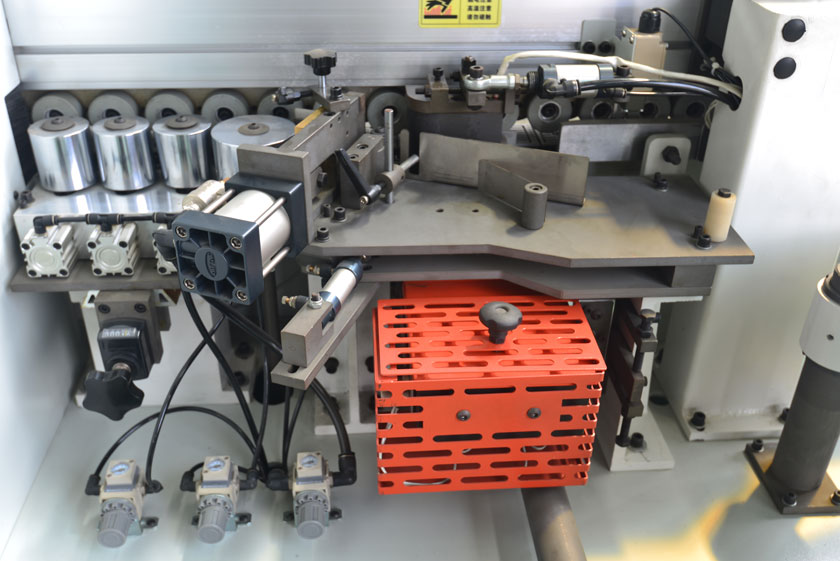

5) Glue coating component: Heat the hot baking glue to melt the well and apply the melted glue to the edge sealing surface of the wooden board. The heating adhesive coating includes some adjustment mechanisms that can be adjusted horizontally to achieve a uniform and even thickness of the adhesive layer applied to the wooden board, ensuring the best edge sealing effect.

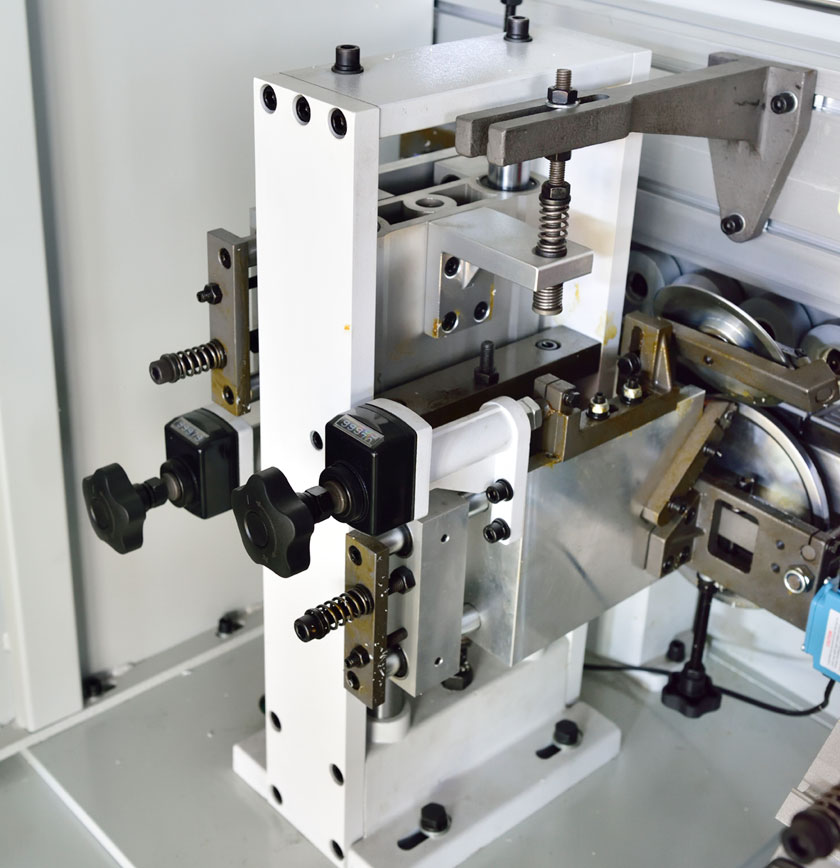

6) Belt cutting: The function is to automatically pull out and cut off the edge banding strip required for the edge banding board from a roll of edge banding strips. The belt cutting mechanism can ensure the smooth and automatic transportation of the edge banding belt by adjusting it, and can also adjust the distance between the bottom edge of the edge banding belt and the lower surface of the wooden board.

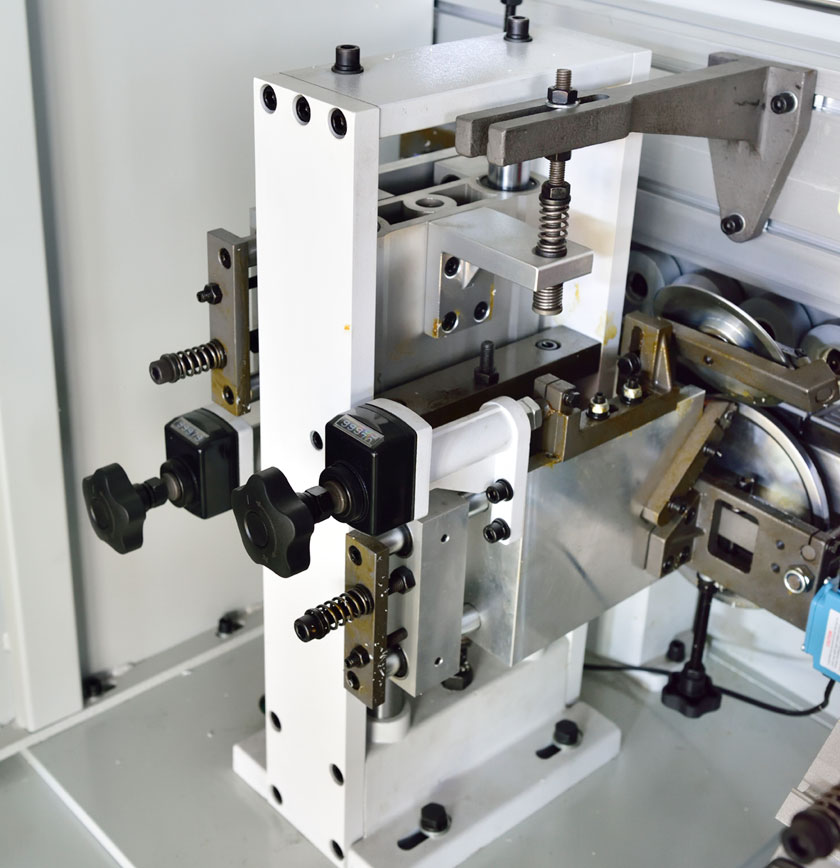

7) Pressing component: Press the edge banding strip onto the edge banding surface of the wooden board coated with glue, and adjust it to ensure that the edge banding strips of different thicknesses can be firmly and evenly bonded.

8) Cutting the head and tail: Cut off the excess edge banding tape that is pasted on the wooden board before and after, so that both ends of the edge banding tape are flush with the front and rear end faces of the wooden board, and a certain chamfer can be cut on both ends of the edge banding tape.

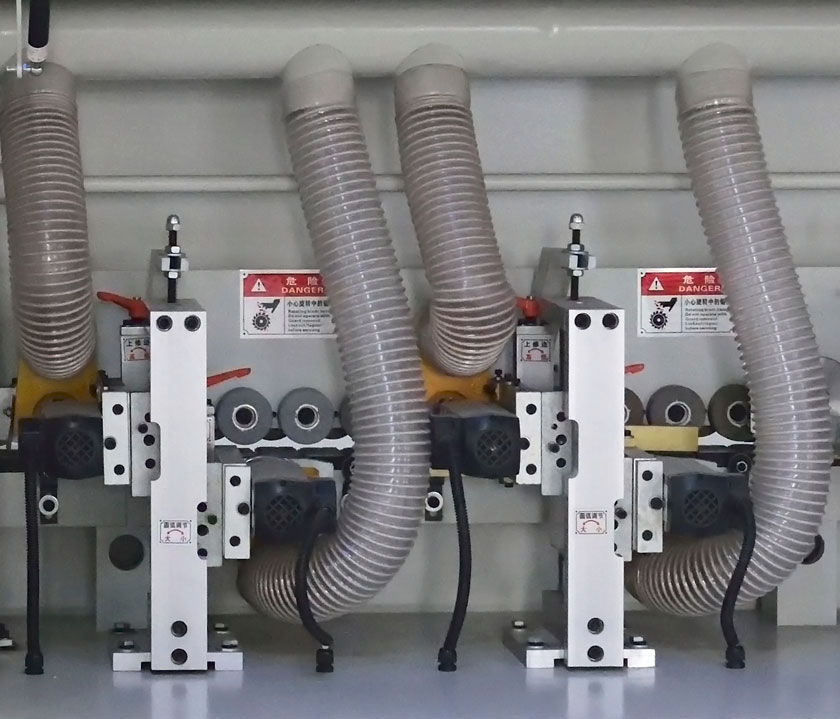

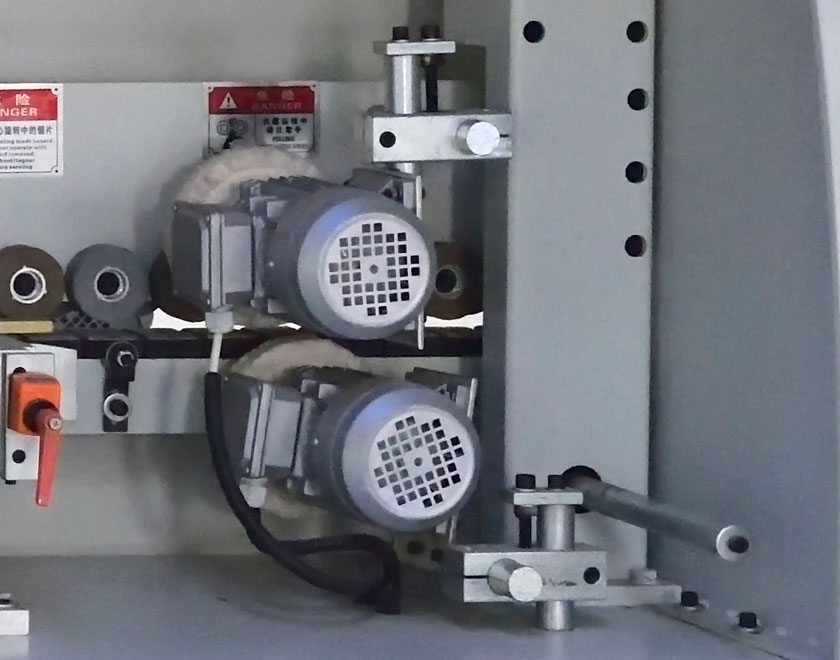

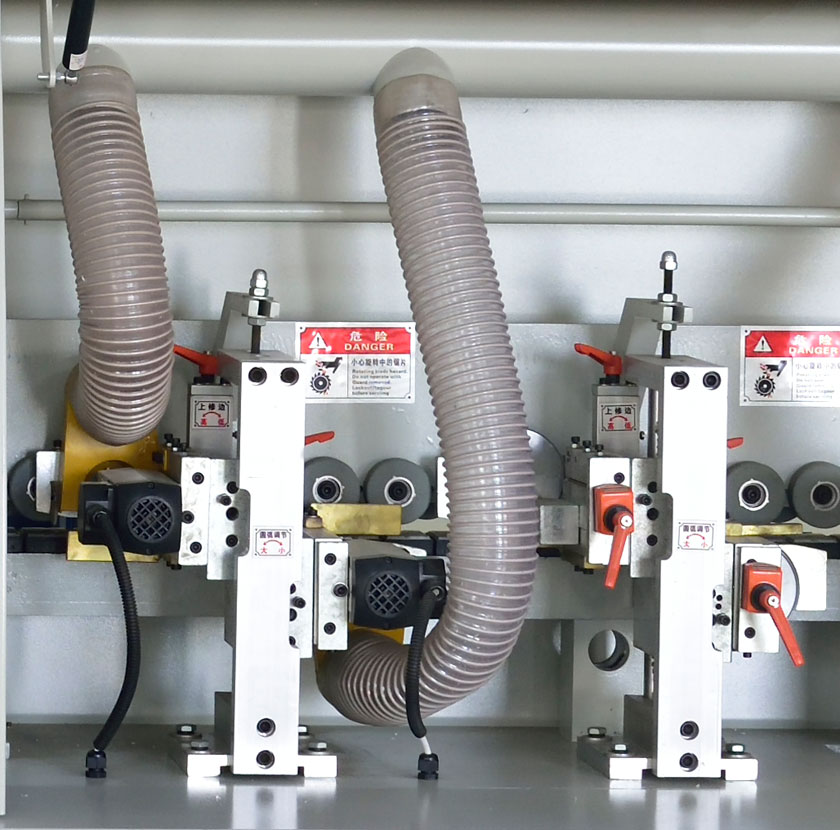

9) Rough trimming: Cut off any excess edge banding that protrudes from the upper and lower surfaces of the wooden board, so that the upper and lower edges of the edge banding are flush with the upper and lower surfaces of the wooden board.

10) Refinement: Cut the excess edge banding that protrudes from the upper and lower surfaces of the wooden board on both sides of the edge banding strip, while chamfering the upper and lower edges.

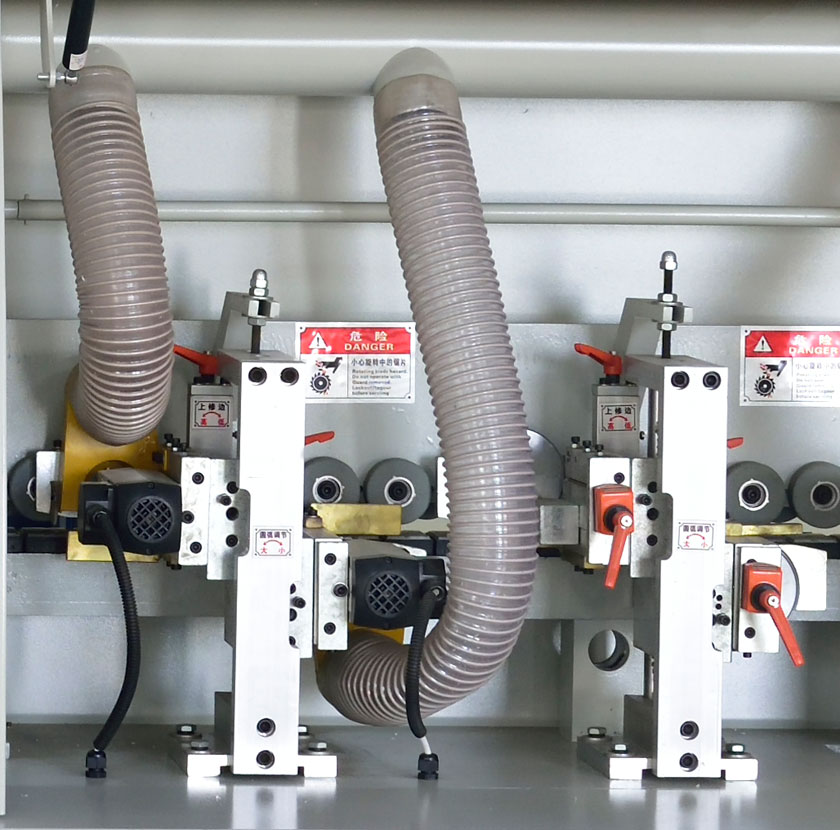

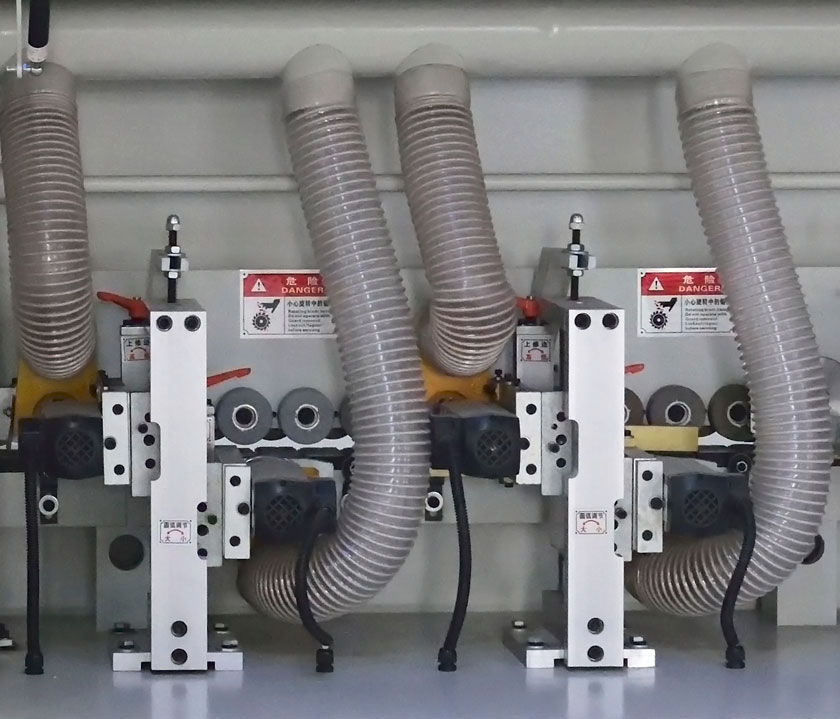

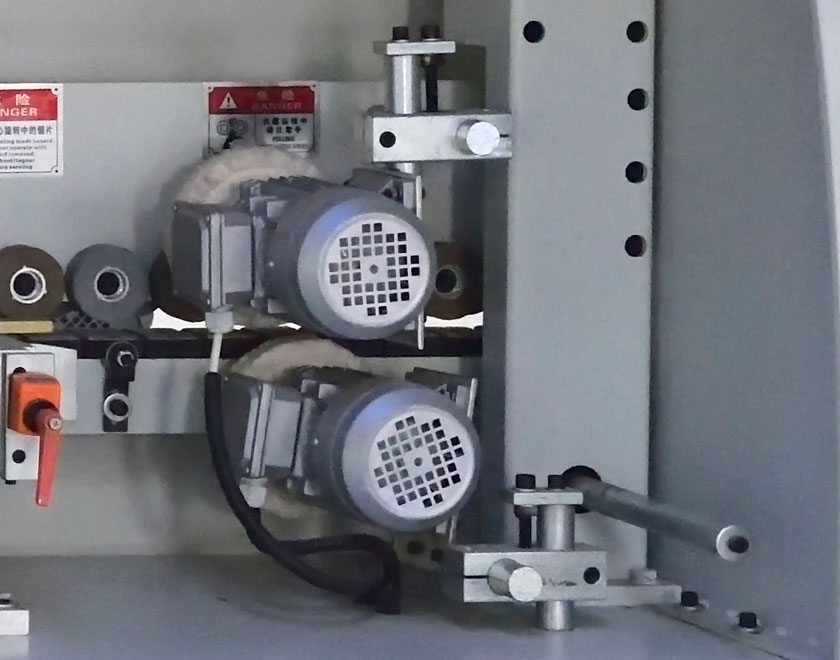

11) Tracking: After the wooden board is sealed, the four corners on both sides of the edge banding strip on the board are very sharp. At this time, the tracking component is used to chamfer into an arc angle, and the motor of the tracking component is used to follow the movement of the board to chamfer, making the sealed board corners more beautiful and smooth.

12) Scraper (R scraper): Remove the blade marks and residual glue left by the trimming knife. Therefore, its installation is directly related to the processing quality of the workpiece.

13) Polishing: Remove the burrs on the edges of the edge banding strip and the residual glue between the edge banding strip and the wooden board, making the edges sealed by the wooden board smoother.

14) Pre milling: The pre milling device uses a cotton polishing wheel to clean the processed board and polish it to make the end face smoother.

15) Slotting: Slotting is used for direct slotting of side panels, bottom plates, etc., reducing the process of cutting board saws and making it more convenient and efficient.

The functions of the edge banding machine can be customized according to your edge banding needs.