Edge banding machine mechanism debugging (1)-Debugging of conveyor chain and pressure roller

1、 Debugging board requirements

Before entering the edge banding machine, the board should be checked to see if it meets the requirements. The moisture content should not exceed 15%. The board is made of wood, medium density fiberboard, or veneer popcorn board, with a width of 300-500mm, a thickness of 20-30mm, and a length of 1000mm. The flatness of the edge banding surface measured at 1000mm is 0.10mm in length.

2、 Debugging of conveyor chain and pressure roller

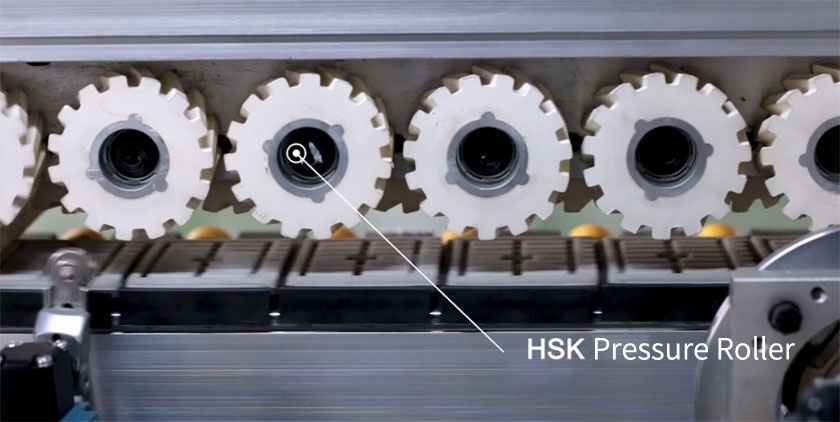

The feeding direction of the conveyor chain and the pressure wheel must be parallel, otherwise the ideal edge sealing effect cannot be achieved. The conveyor chain and pressure roller are one of the key factors determining whether the sheet can be straightened

After the installation of all pressure wheels, their center height and the downward tangent of the wheel edge should be equal to the distance between the conveyor plate chain (the size of the wheels should be consistent).

Attention: The tightness of the wooden board can be adjusted through the lifting and lowering handle of the pressure beam. If the pressure is too tight, it will leave pressure marks on the wooden board, and if it is too loose, it will not achieve the ideal edge banding machine effect.

3、 Ruler debugging

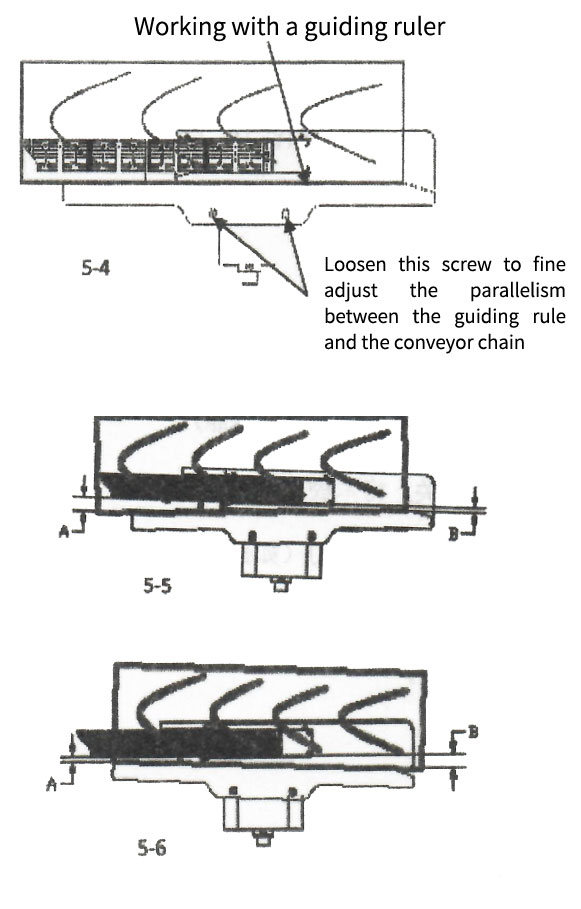

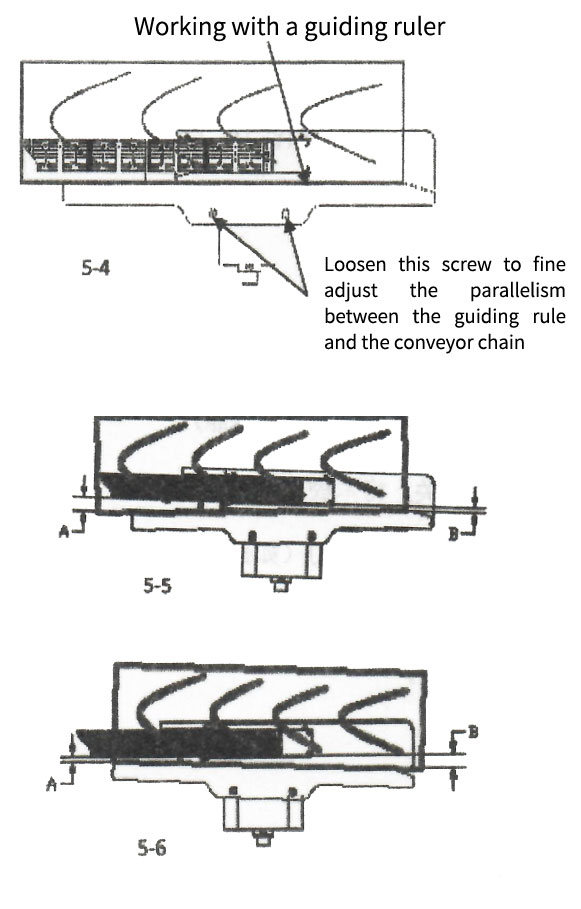

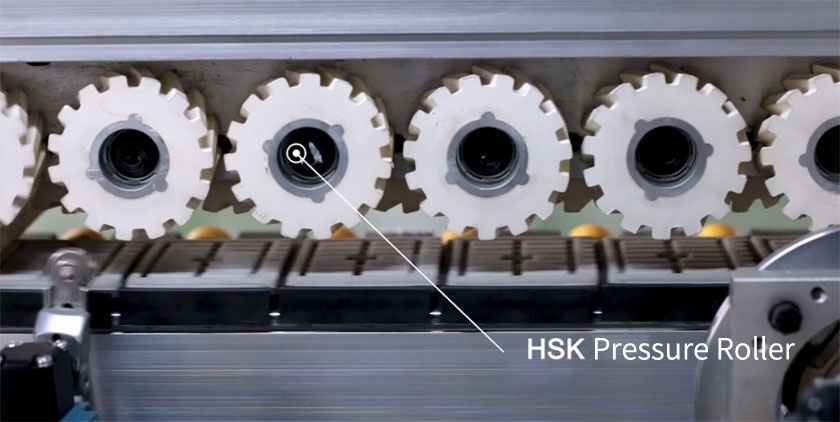

The function of a guiding rule is to provide a lateral reference when placing the board to be sealed. Under normal circumstances, pressing the ruler tightly to feed can ensure that the edge of the wooden board to be sealed is parallel to the direction of movement of the conveyor belt. During processing, the edge surface of the wooden board to be sealed should be close to the working surface of the ruler (as shown in Figure 5-4).

The working surface of the guiding rule must be parallel to the feeding direction of the conveyor chain, with a distance initially set at 35mm; When the working surface of the guiding rule is not parallel to the feeding direction of the conveyor chain, i.e. A ≠ B, as shown in Figures 5-5 and 5-6, debugging is required. After adjusting, turn on the edge banding machine, press the power button on the operation box panel to turn on the conveyor belt, and adjust the speed of the conveyor belt to low speed. Other edge banding machine functions will not be turned on for now. Place an unsealed wooden board correctly, push the board slightly to make it close to the guiding rule, and pay attention to observing whether the edge sealing surface of the board and the working surface of the guiding rule are tightly attached before and after the transportation process. The proof of adhesion is parallel, and the proof of non adhesion still needs to be debugged.