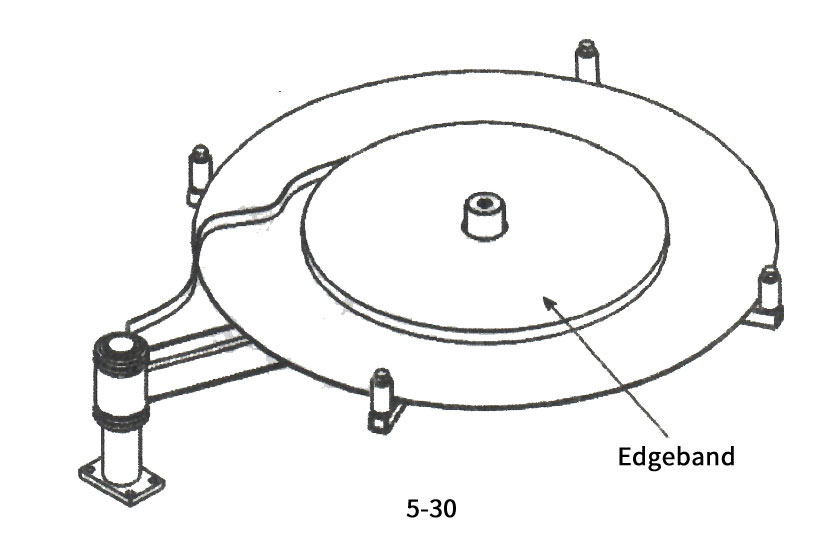

Edge banding machine mechanism debugging (4)-Disc components

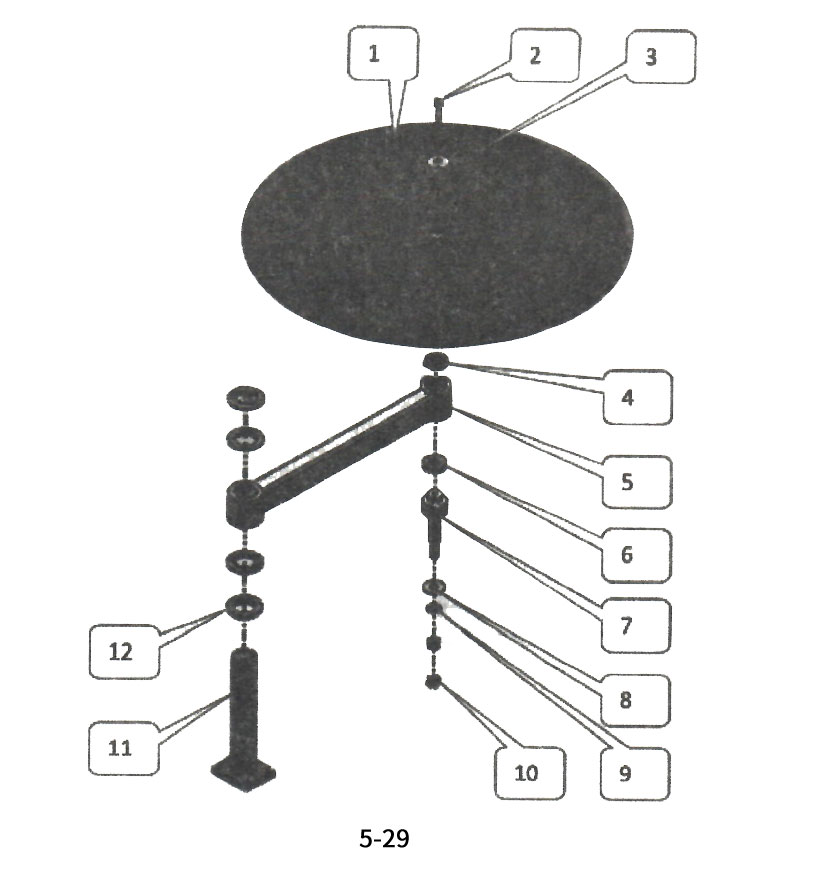

1. Introduction to the names of edge banding machine with disc components

The disc mechanism is rotatable and used for placing edge banding strips. The disc surface is on the same plane as the adhesive coated plate, making it easier for the edge banding strips to be fed horizontally.

1) Putting on a disc

2) Hexagon socket screw

3) Locking shaft

4) Deep groove ball bearing

5) Bracket

6) Thrust ball bearing

7) Rotating shaft with disc

8) Belleville spring

9) Elastic washer

10) Outer hexagonal nut

11) Support tube

12) Round nut

2. The action process of the disc mechanism